How Does Commercial Reverse Osmosis Work?

Water filtration systems such as reverse osmosis are being used more commercially due to the success they have in the industrial process.

The process of installing a reverse osmosis system for commercial use mirrors that for industrial use as each system is bespoke to the water issue.

Download The Guide To Water Filtration In Industrial Processes

What Is Reverse Osmosis?

Reverse osmosis is a water filtration solution system that removes impurities from a raw water source. It forces pressured water through a membrane, capturing a concentrate of the impurities that were in the raw water. Leaving you with pure water to use in production.

Reverse osmosis can reject 99.9% of bacteria, making it highly effective for commercial use such as pharmaceutical production.

Membrane-based solutions such as RO are becoming increasingly popular due to the many benefits, these include:

- Environmental

- Cost savings

- Health and safety

- Maintenance

How Does Reserve Osmosis Work?

To understand how reverse osmosis works, lets first explain how osmosis works.

Let’s start with 2 cups, one has plain water in, the other has water and sugar dissolved into it. A U-tube is then used, which is a beaker-shaped in a U-shape.

Right in the middle of the tube, imagine a bit of Gore-Tex that cuts the U in half. Gore-Tex is our “semipermeable membrane.” Gore-Tex is thin plastic, dotted with a billion tiny little holes that allow water vapour to pass through, but liquid to stay out.

In one arm of the U-tube the plain water is poured, in the other is the sugar water. This is when the osmosis process begins. The level of liquid in the sugar water arm will slowly rise, as the plain water moves through the Gore-Tex, to make both sides of the arm more equal in a sugar-to-water ratio.

This is due to the water finding an equilibrium. Because the one side of the arm is crowded with sugar, pure water from the other side decides to move on over to make the concentration more equal or until the osmotic pressure (the pressure that happens as the molecules move) is reached.

In osmosis, a lower-concentrate solution will filter its solvent to the higher concentrate solution. In reverse osmosis, we are just reversing the process, by making our solvent filter out of our high concentrate into the lower concentrate solution. So instead of creating a more equal balance of solvent and solute in both solutions, it is separating out solute from solvent (the sugar from water).

This isn’t something that solutions really want to do so pressure is added to the equation to make reverse osmosis occur. Pressure forces the water to pass through the membrane, removing the impurities in the water.

How Can RO Be Used Commercially?

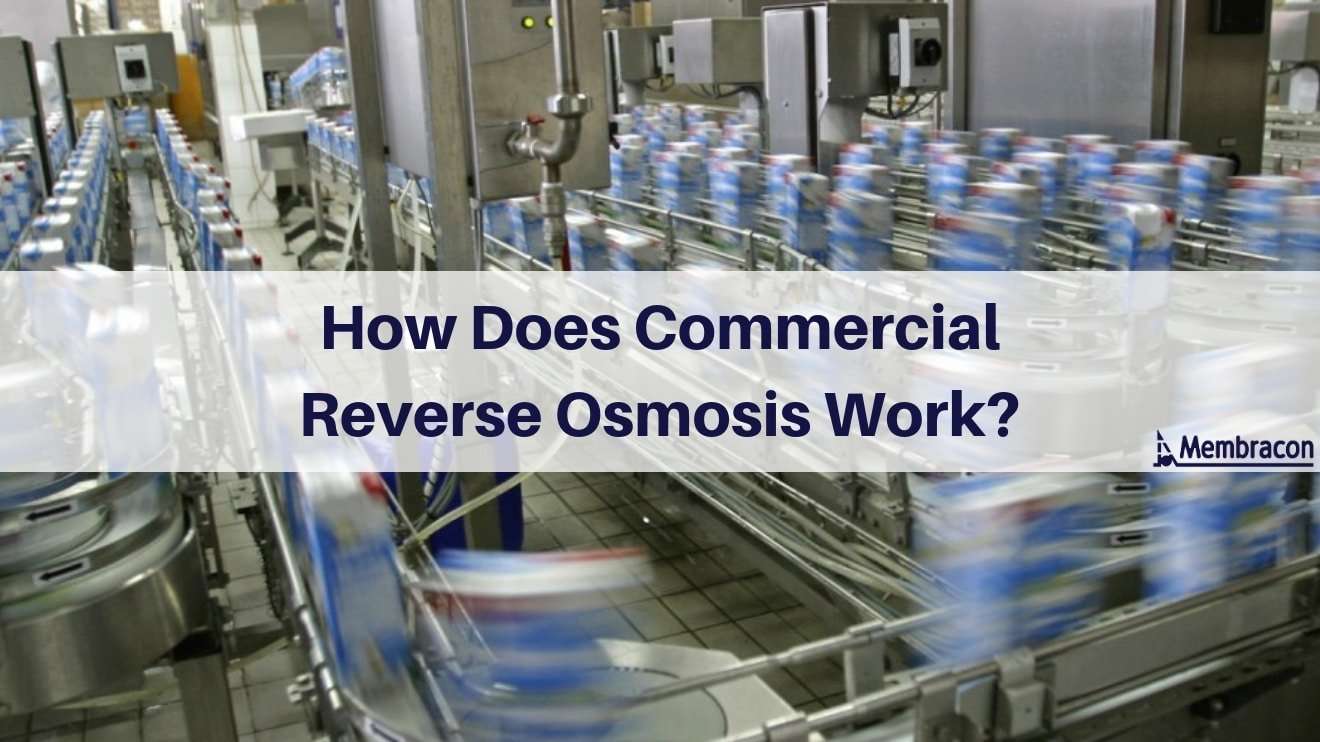

RO systems can be put in place commercially and function the same way as in industrial processes. Each RO system features are dependent on the quality of water you want to reach and are tailored to manage the raw water issue you have.

RO systems can be used commercially in sectors such as food, beverage, dairy, pharmaceutical and more.

Conclusion

The process of reverse osmosis can be used commercially the same way it is industrially, providing a green solution for water treatment.

Membracon tailors each system to suit their client’s water issue, with every unit designed and built fully bespoke.

Still not sure if reverse osmosis is right for your business? The first step is establishing the quality of raw water you have and the water you need to achieve. Membracon offers a free water analysis test to help you with this process. Please contact us to arrange today.