Can water recycling assist to achieve Carbon Net-0?

Reducing greenhouse gas emissions is one of the biggest challenges of our generation and essential if we are going to slow global warming.

For years, we have been told that climate change is inevitable and irrefutable. However, the latest scientific research tells us that global warming (which causes climate change) will level of if emissions are cut to net zero.

What is net-zero or net-0?

Net-zero is when greenhouse gas emissions are balanced by the removal of greenhouse gases from the atmosphere. In other words, we take away as much as we add.

The UK and many other countries are aiming for “net-zero” greenhouse gas emissions by 2050, which will require sweeping changes in the ways we produce, use and reuse energy, and the water industry has a significant role to play.

How does water usage relate to carbon emissions?

The water industry directly contributes 1% of the UK’s greenhouse gas emissions through electricity, process emissions and transport. In particular, water extraction and treatment are extremely energy intensive processes.

In addition, global water utilities report a loss of around 40% of clean water due to leakage, adding unnecessary emissions to the process.

The UK water industry has a 10-point plan for decarbonisation with a 2030 net-zero target, including the production of biomethane from waste, the development of renewable energy, restoring peatland and grassland, and transitioning to electrifying vehicles.

However, industrial processes also need to be carbon neutral, and when it comes to water, water recycling is the most viable solution

How could water recycling help?

Water recycling reclaims spent water in industrial processes, treats it, and puts it back into circulation, creating a closed-loop water supply.

A closed-loop water supply assists with carbon net-zero in several ways:

- Manufacturers reduce dependency on freshwater resources, eliminating the need for extraction.

- Manufacturers decrease the amount of wastewater that is discharged into the environment.

- Manufacturers cut out emissions related to freshwater supply, including transport and off-site treatment.

- Manufacturers take control of their water supply, innovating recycling processes in-house to maximise efficiency and flow.

Water recycling reduces waste and provides a consistent supply of treated water. When designed correctly, it can reduce dependency on freshwater by more than 90%, slashing a company’s industrial process carbon emissions.

Although water recycling is energy-intensive, with pumps, blowers and aerators drawing the most power in treatment systems, it is net-zero, with the emissions generated from it less than the emissions associated with water extraction.

Building on water recycling

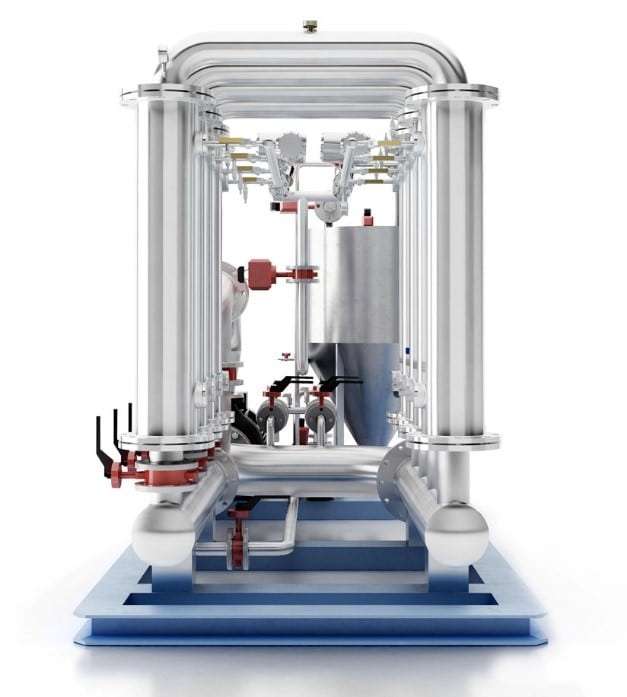

Membracon is helping manufacturers transform their water use with industry-leading recycling technologies. We aim to create a circular economy in industrial water use, where water, effluent and trade waters are re-used to achieve carbon net-zero.

If you’re interested in the technologies used in water recycling, Membrane Bioreactors (MBRs) are the most common water recycling systems for small-medium scale recycling, supporting flow rates up to 2,000m3 a day

By re-using water, you can extract less water, cut transport emissions, and avoid the heavy emissions associated with water supply. Why turn on the tap, when you can feed processes with water you already have at your disposal?

Call us on 01902 458501 to find out more about water recycling solutions.