A Comprehensive Guide to Forward Osmosis

Forward osmosis (FO) is an innovative water treatment technology that uses a semipermeable membrane and natural osmotic pressure to separate pure water from contaminants and produce a clean water supply.

How forward osmosis works

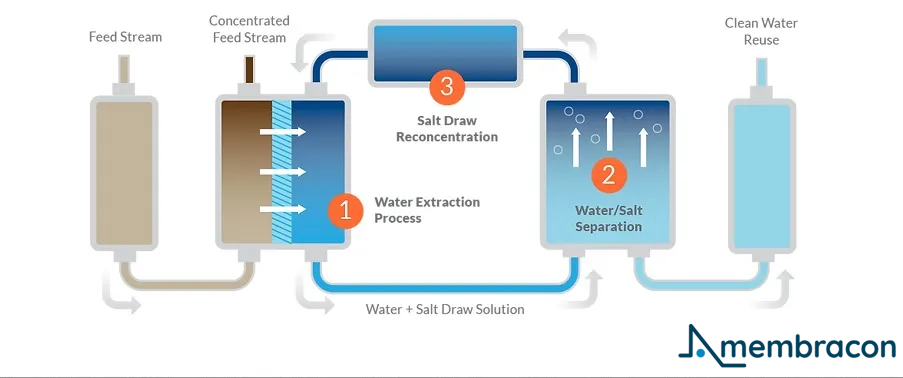

In FO, a feed solution like wastewater flows on one side of a membrane, and a concentrated draw solution flows on the other with a higher salinity, creating an osmotic pressure gradient. This natural force pulls the water from the feed across the membrane into the draw solution. The result is a diluted draw solution and a concentrated feed solution.

Unlike reverse osmosis, FO doesn’t require external hydraulic pressure to filter the water. It only uses the chemical potential between the solutions, making it less prone to fouling and scaling and more energy efficient.

What’s needed for an FO system?

There are three critical components in an FO system:

- The FO membrane – rejects contaminants while allowing water to pass through. It needs high rejection rates and robustness against fouling.

- The draw solution – this is a brine solution formulated to create optimal osmotic pressure. As it dilutes, it must be reconcentrated.

- A draw recovery system – separates the filtered water from the draw solution so both are reusable.

FO membrane

The membrane is the heart of the forward osmosis process. It must allow pure water to pass through while rejecting contaminants at a high rate. The rejection efficiency, or the rate at which it blocks solutes, is a crucial metric for an effective FO membrane.

Beyond a high rejection rate, the membrane must also be robust against fouling from the feed solution. It should withstand elevated substances like COD and TOC that can foul or scale the membrane over time. Strong resistance to fouling allows the FO process to handle challenging industrial wastewater.

Minimising reverse salt flux is another essential criterion. The best FO membranes allow very little solute to diffuse from the draw solution into the feed, helping reduce the need for draw solution top-up.

The draw solution

The draw solution provides the osmotic pressure gradient that drives separation. It needs to precisely match the composition of the feed effluent. The solution must create optimal osmotic pressure across the membrane to induce high water flux.

The draw solution also needs to be reconcentrated after becoming diluted by the filtered water. Therefore, it should be compatible with the planned draw recovery system.

The draw recovery system

The draw recovery system separates the filtered water from the diluted draw solution so both can be reused continuously. Most systems use reverse osmosis tuned to handle the high TDS draw solutions, up to 70,000 ppm. The clean permeate can then be recycled into the industrial process or reused for other purposes.

Some advanced systems use novel draw recovery methods that can handle up to 250,000 ppm TDS. The draw recovery system impacts how concentrated the draw solution can become before needing regeneration. More robust systems allow more substantial osmotic pressure to be generated during the FO process.

What are the benefits?

FO offers several advantages over other water treatment methods:

- High rejection of contaminants with lower fouling potential.

- Enables water recycling and reuse.

- More energy efficient than pressure-driven processes.

- Concentrate products like food and beverages gently.

- Simplifies wastewater treatment and improves recovery rates.

- Reduces cost of zero liquid discharge (ZLD) systems.